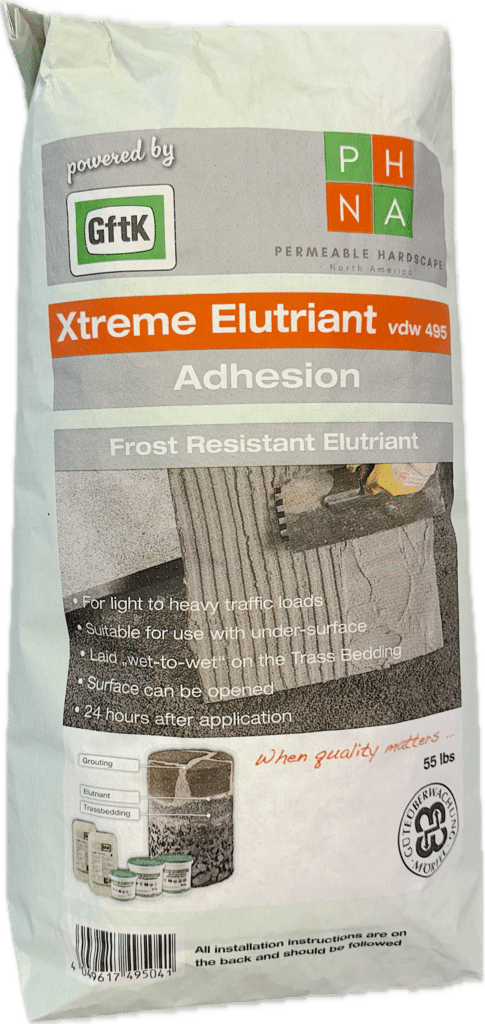

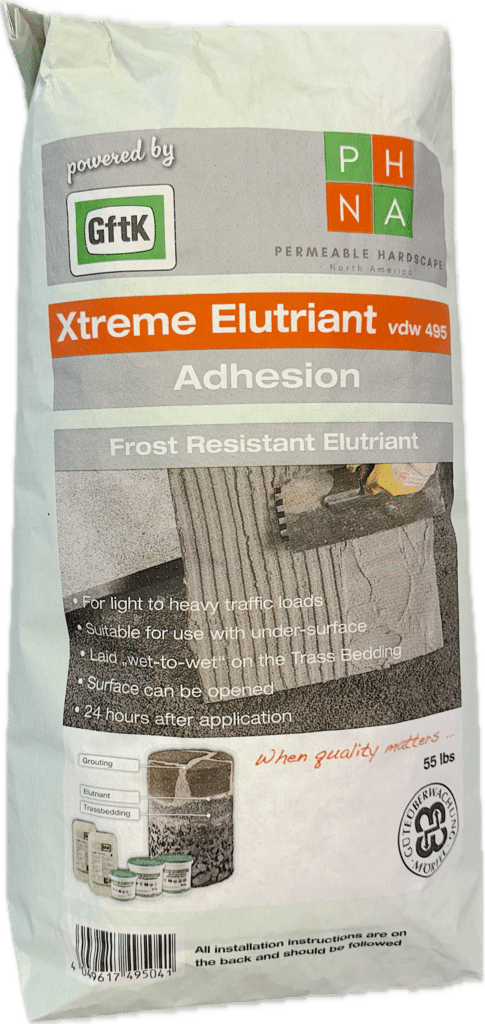

Why Use The VDW 495 Xtreme Adhesion Elutriant?

Improved Water Resistance

Our joint compound adhesive is designed to withstand extreme weather conditions, making it perfect for outdoor use. The adhesive mortar is resistant to frost, rain, and heat, ensuring that the bond between your pavers remains intact no matter the outdoor conditions. If you have extreme weather fluctuation where you live, VDW 495 is perfect for you.

Long Lasting

The VDW joint compound adhesive mortar is suitable for indoor and outdoor uses. Whether you are working on a patio or pathway, this high-performance adhesive mortar will provide the perfect bonding solutions for many years. You are ensuring that your pavers will not become loose or dislodged.

Low Maintenance

This adhesive mortar requires very little maintenance once it is applied. This bonding solution is resistant to water, dirt, and other environmental factors, ensuring your pavers stay in place and do not require maintenance.

Cost Effective

The VDW joint compound adhesive mortar is a cost-effective way to improve the adhesive between pavers. Our adhesive mortar is available at a very affordable price., making it an excellent choice for large-scale projects.

Technical Product Data

| Product Size | Comes in a 55 lb bag |

| Application Time | Approx. 1 hour at 20°C | 68°F* application temp. *Quick hardening at higher temperatures, and slow hardening at lower temperatures. |

| Coverage | 70 – 85 ft depending on stone type and application method |

| Mixing Time | 2 minutes until homogeneous, followed by 2 minute maturation time, then briefly mix again |

| Water Addition Approximation | 5 to 7 liters | 1.3 to 1.8 gal. of cool, clean water per 25 kg | 55 lb. bag depending on processing type |

| Application Temp. | 5-25°C | 41-77°F (Do not lay onto frozen ground.) |

| Adhesive Strength | Approx. 1015 psi |

| Ingredients | Standard cement with additives, low in chromate according to TRGS 613 |

| Storage Life | 1 year if stored unopened in sealed and undamaged packaging. Must also be kept dry and frost-free. |

Recommended Mixering Tools:

Option 1: X055 Double Paddle Mixer

This Dual Paddle Mixer Offers the Highest quality materials and the finest German engineering. It’s the most reliable product on the construction site. Proven hundreds of thousands of times on job sites all over the world.

Recommended Mixering Tools:

Option 2: X04 R Paddle Mixer

A robust 2-speed Machine for universal building materials and large mixing quantities. With a 1.7 HP motor, it has two speeds and a throttle switch to give you more control. Specially designed ergonomic handles reduce fatigue, while a raised handlebar allows for an upright working position to eliminate back strain.

Application Instructions for Xtreme Adhesion Elutriant VDW 495

1

Construction Site Requirements

- The subsurface must be made load bearing, firm and water permeable; all elements should be constructed based on the highest expected traffic loads.

- Foundation should be stable as to not allow any future surface settling or loosening of pavers under these traffic conditions. Ideally, the setting bed would be the PHNA Xtreme Bedding Compound (vdw 480).

- Ambient and substrate temperature should be 41-77°F, and the process should be carried out in dry weather.

2

Preparation

To ensure a clean bond between the Xtreme Adhesion Elutriant and the paving unit, the connecting elements should be clean and free of any dust/debris that would otherwise prevent that.

3

Mixing

- Notched Trowel Method

- 25 kg | 55 lb. bag of Xtreme Adhesion Elutriant to be mixed

with approx. 5 liters (1.3 gal.) of cool, clean water. - Mixing partial quantities to be used in the specified processing time is recommended

- 25 kg | 55 lb. bag of Xtreme Adhesion Elutriant to be mixed

- “Dip” Method”

- This method should only be used for cobblestone installation.

25 kg | 55 lb. bag of Xtreme Adhesion Elutriant to be mixed with approx. 7 liters (1.8 gal.) of cool, clean water - Mixing partial quantities to be used in the specified

processing time is recommended - According to the specified mixing ratios, pour the requisite amount of water into a container. Add in the proper proportion of the Xtreme Adhesion Elutriant and mix the slurry with a suitable drill/ paddle mixer for 2 minutes until homogeneous. Let the mixture mature for 2 minutes before briefly mixing again. Hardened mortar must not be made workable again.

- This method should only be used for cobblestone installation.

4

Application

Installation of paving units with the Xtreme Adhesion Elutriant bonding slurry can be carried out in one of two ways, and should be done so based on the type of paving unit utilized. For natural stone slabs, porcelain tile, and concrete pavers, please follow the “Notched Trowel” method. For small paving units such as cobblestones, the “Dip” method is a viable alternative.

- Notched Trowel Method

- A 1/4″ x 1/4″ notched trowel is recommended.

- Using the notched trowel, apply the Xtreme Adhesion Elutriant slurry to the clean underside of the paving unit, ensuring to cover it completely. Any spillage onto the sides of the paving unit should be immediately wiped clean with a damp sponge or cloth – this will provide a clean joint for the jointing compound that will later be used. The paving unit should be immediately laid in the still-fresh drainage mortar (“wet-to-wet”), and solidly set into place with the use of a rubber mallet or dead-blow hammer. The Xtreme Adhesion Elutriant must be protected from rapidly drying out

- “Dip” Method

- Dip the paving unit 3/4″ – 1 1/4″ deep into a tub of the Xtreme Adhesion Elutriant. Then hammer the paving unit into the still-fresh drainage mortar using an appropriate rubber mallet or dead-blow hammer.

5

Important Information

- The surface can be walked on after 24 hours.

- Grouting can also be carried out at this time.

- Protect the mortar from rapidly drying out, as well as rain, for 12 hours.

- Full resilience will be reached after 7 days, but vehicular areas should not be opened to traffic until the grout has also sufficiently cured.

- Paved stone work is done by hand – no compaction machinery should be used.

- Expansion joints should be laid according to

relevant guidelines. - Underside of sawed stones should be roughened prior to application of the Xtreme Adhesion Elutriant.

GFTK Consumption Calculator

Use This GFTK calculator to find out how much product you need!

Please Note For The Calculator:

Calculations will only occur if all fields are filled in correctly.

Please ensure that a 0. is listed where the dimensions are under an inch.

For The Xtreme Elutriant:

Coverage is approximately 75 sq ft per bag of VDW 495.

Please View This PDF for Additional Information