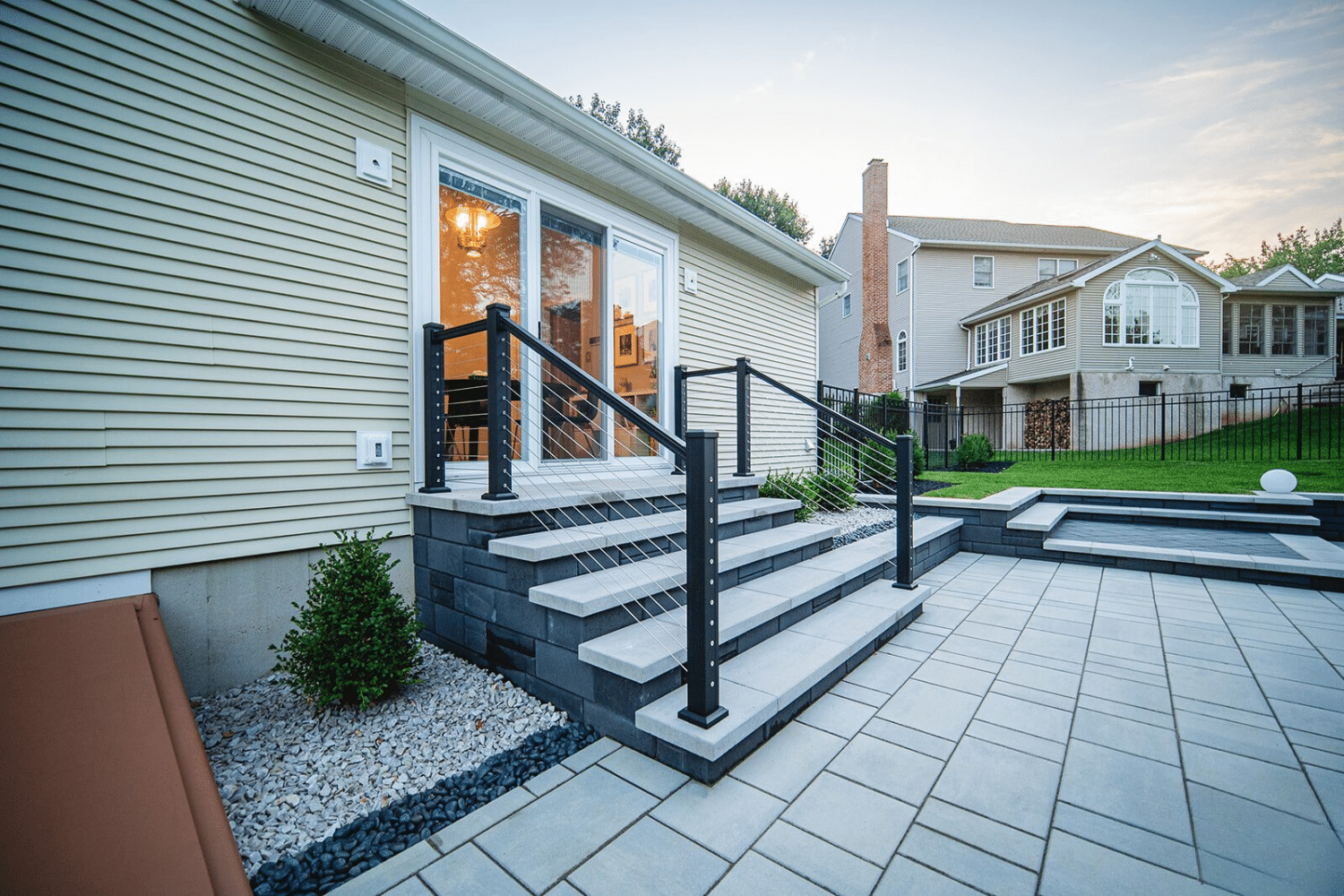

The VDW 480 Frost Resistant Drainage Mortar offers exceptional features for your paving needs. It excels as a permeable bedding system, providing both frost resistance and robust structural support for your paving stones. Trust in VDW 480 for durability and a reliable foundation that stands up to the elements

Our Mortar bedding is permeable, making it ideal for use in areas exposed to extreme moisture or water, such as swimming pools, fountains, and water tanks. This type of mortar is highly durable and can withstand harsh conditions, including extreme temperatures, rain, and snow.

Trass bed VDW 480 Mortar has excellent strength properties, making it suitable for heavy-duty applications such as driveways that bear more weight than a standard patio. Our mixture is optimized to last a long time without requiring constant maintenance.

Trass bedding mortar is known to be cost-effective even though it might be slightly more expensive than other types of mortar, such as traditional cement. While the initial investment might be more significant, it will pay off in the long run as our mortar bedding doesn’t require as much costly maintenance and repair. In addition, the improved workability of our mortar bedding means it can save money on labor costs because of the quick application.

The Trass is a volcanic tuff used in the production of mortar and is a natural material that is mined from the earth. The Trass is a renewable resource that is more sustainable than many other building products that are derived from non-renewable sources. Trass VDW 480 mortar bedding is also considered a great eco-friendly material.

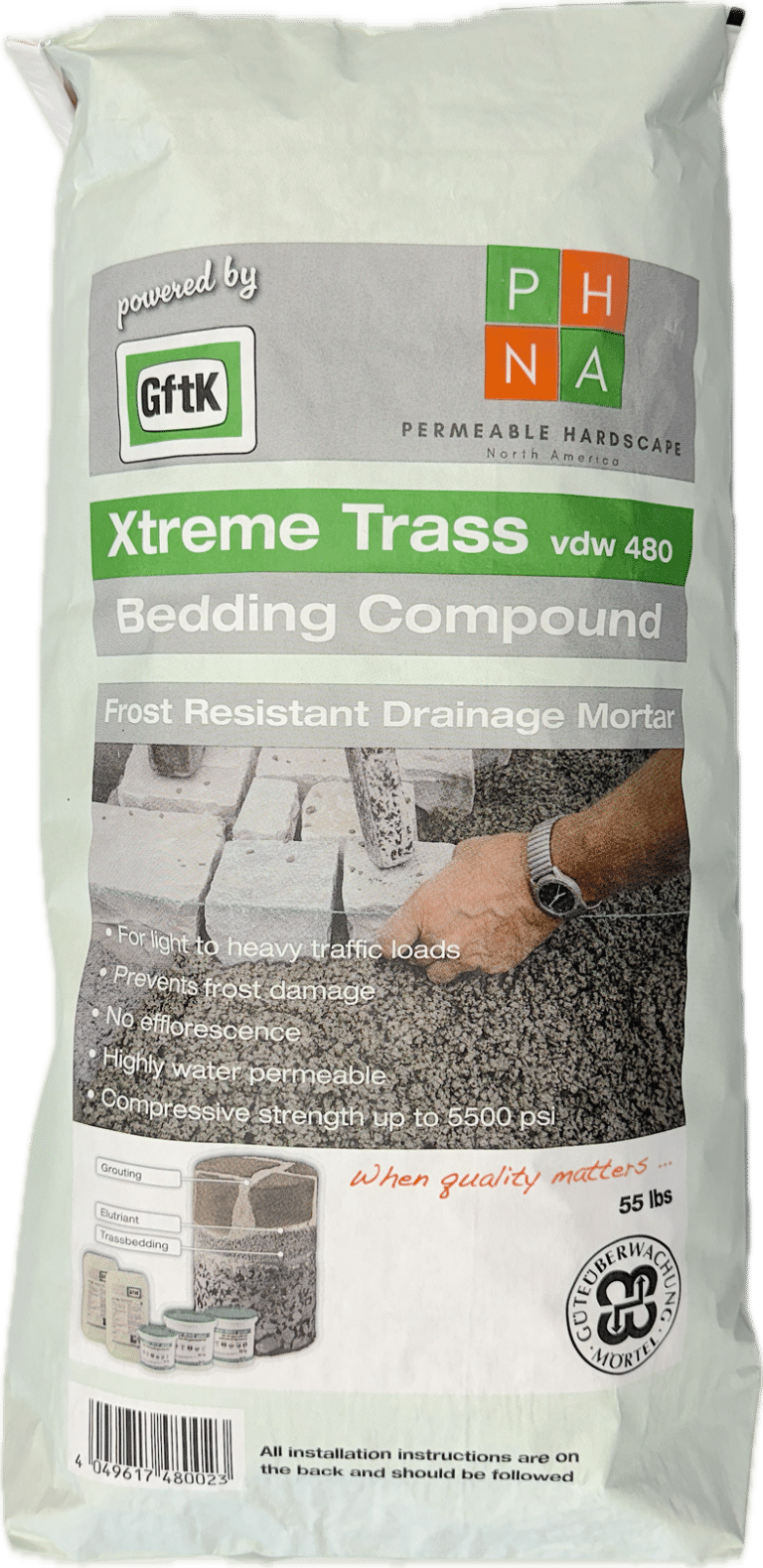

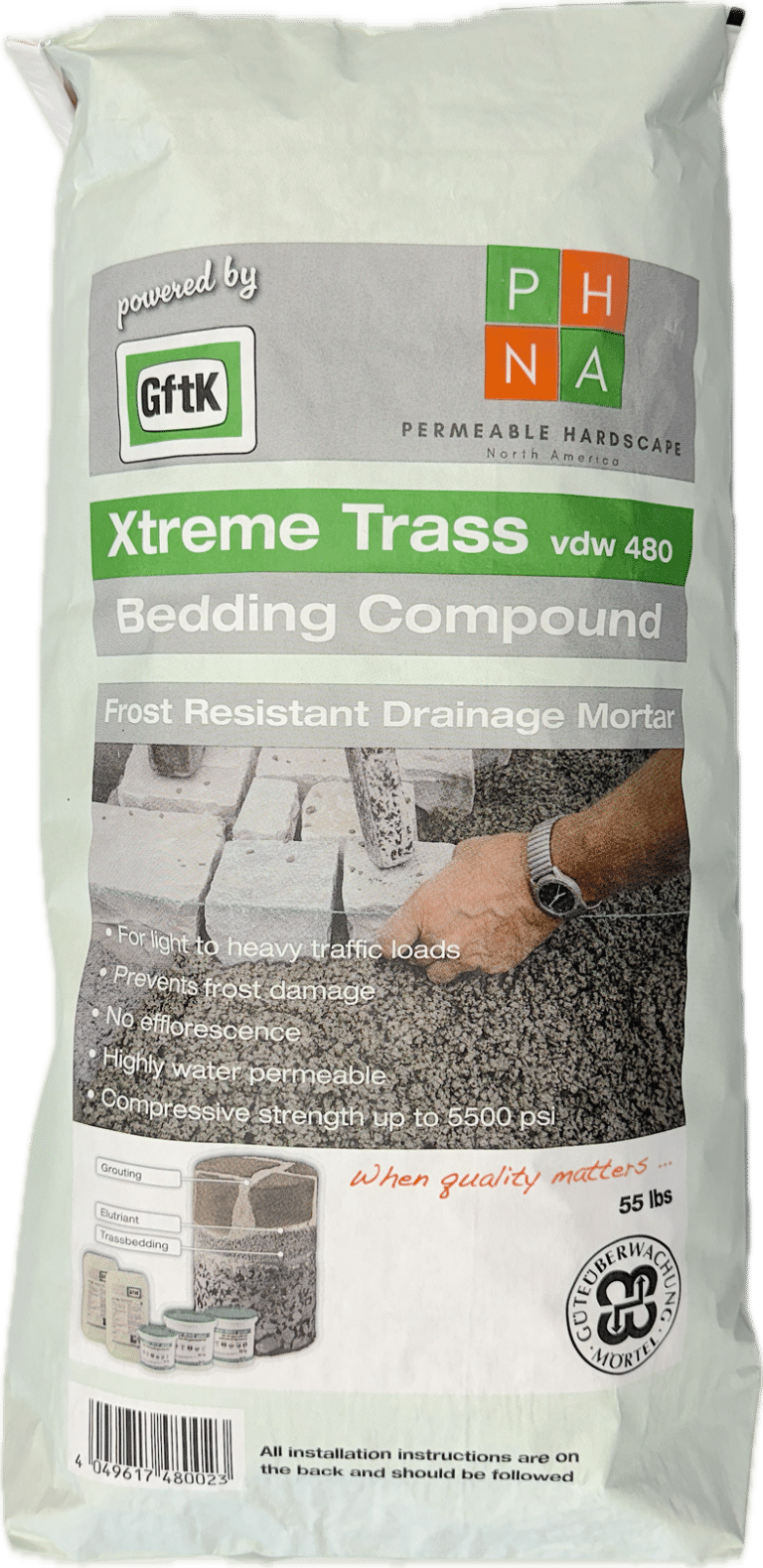

| Product Size | Comes in a 55 lb bag |

| Application Time | Approx. 1 hour at 20°C | 68°F* application temp. *Quick hardening at higher temperatures, and slow hardening at lower temperatures. |

| Compressive Strength | 2900 – 5500 psi at 3 and 28 days (dependent on filler material and mixing ratio) |

| Material Requirement | Clean 1/8″ – 3/8″ crushed aggregate mixed at 1:4 ratio 1 part Xtreme Bedding Compound to 4 parts aggregate (approx. 220 lbs. aggregate per each 55 lb. bag of bedding compound) *Mixing ratio of 1:6 is possible and suitable for light pedestrian loads |

| Water Addition Approximation | 11 liters | 2.9 gal. of cool, clean water per 25 kg | 55 lb. bag of mortar mixture |

| Application Temp. | 5-25°C | 41-77°F (Do not lay onto frozen ground.) |

| Flexural Strength | Approx. 1015 psi |

| Ingredients | Cement according to EN 197, Trass according to DIN 51043, and special additives |

| Storage Life | 1 year if stored unopened in sealed and undamaged packaging. Must also be kept dry and frost-free. |

The Collomix TMX 1000 & 1500 are compact, powerful automatic mixers specially designed for pre-bagged, heavy materials.

Three precisely angled arms spin at a low rotation to thoroughly mix up to three bags of heavy materials. Let the TMX mixers mix so you can be productive on the job site.

Please Note For The Calculator:

Calculations will only occur if all fields are filled in correctly.

Please ensure that a 0. is listed where the dimensions are under an inch.

For The Xtreme Elutriant: Coverage is approximately 75 sq ft per bag of VDW 495.