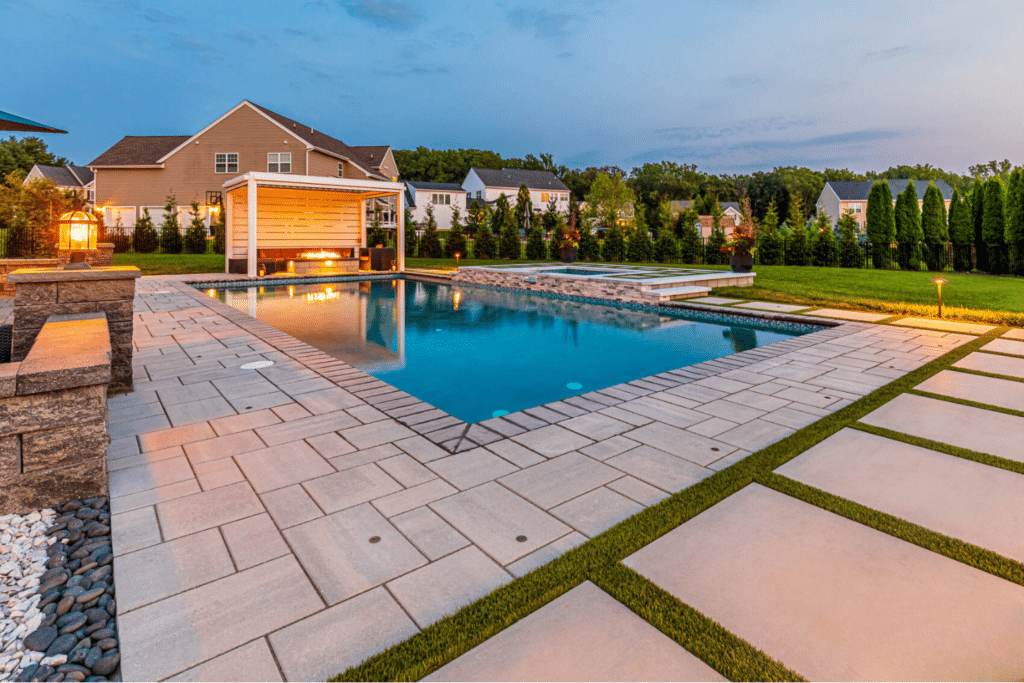

Why Use The VDW 520 GtfK Xtreme Gravel Lock?

The GFTK Xtreme Gravel Lock is a 2-component epoxy to be mixed with any clean aggregate to provide solutions for pathways, wide paver joints, tree pits, and more.

Pressure Washer Friendly

With any Joint compound, having it be self-compacting allows for increased strength by minimizing voids between pavers.

This creates a tighter bond and seal! With this feature, there is no need for additional compacting equipment during installation.

Water Permeable

Being permeable means that water will flow through the compound. This is especially important to have in freezing and thawing climates. This keeps the stones dry while reducing water runoff from rain or irrigation systems, allowing water to drain into the ground. This water soaks into the earth, recharging our groundwater and slowing erosion.

Very High Resistance To Yellowing

It can withstand anything from heavy foot traffic and moisture to UV exposure and chemicals.

This makes it ideal for high-traffic areas and outdoor applications. With this gravel lock, your project will stay beautiful for years to come!

High UV Resistance

Included in its strengths is that the epoxy has the ability to avoid degradation caused by the absorption of UV radiation.

This will allow your project to stand the test of time for much longer. Especially while being in consistent sunshine.

Technical Product Data

| Product Size | Comes in a 11 lb box |

| Water Permeability | Very High |

| Mixing Ratios | The contents of one unit (5 kg) can bind a maximum of about 240 lbs. of aggregate (~160 lbs. glass chippings) (Both bottles of A & B components have 1/4 delineation markings to accommodate mixing in smaller batches) |

| Minimum Depth Requirements | 1.5” for aggregates less than 1/2” in diameter. For aggregates greater than 1/2” in diameter, depth must equal min. 3x avg. Diameter. For vehicular traffic: The product must be laid on a permeable concrete or mortar bed (we recommend GFTK Xtreme Bedding Compound / VDW 480) |

| Application Temp. | 2-26°C | 37-80°F (Do not lay onto frozen ground.) |

| Ingredients | Standard cement with additives, low in chromate according to TRGS 613 |

| Storage Life | 12 months, dry, and in an original sealed container. Do not store at temperatures above 20°C / 68°F |

Recommended Mixing Tool:

The TMX 1000 & 1500

The Collomix TMX 1000 & 1500 are compact, powerful automatic mixers specially designed for pre-bagged, heavy materials.

Three precisely angled arms spin at a low rotation to thoroughly mix up to three bags of heavy materials. Let the TMX mixers mix so you can be productive on the job site.

Application Instructions for Xtreme gravel lock VDW 520

1

Construction Site Requirements

- For pedestrian areas:

- A stable and well-compacted gravel/sandbedding layer.

- The depth of the PHNA Xtreme Gravel Lock should be a minimum of 1.5” after compaction and finishing.

- For vehicular traffic:

- The product must be laid on a permeable concrete or mortar bed – we recommend the PHNA Xtreme Trass Bedding Compound (vdw 480).

- All elements must be correctly designed and installed for the anticipated traffic loads and in accordance with ASTM. The Xtreme Gravel Lock cannot be used to compensate for any settlement of the substructure.

2

Preparation

- General Preparation:

- Clean the base material and any joint sides to ensure no contaminants or uncompacted materials are present.

- Mask any adjacent areas not to be jointed to prevent any spots or staining from the epoxy.

- Prior to Installation, we recommend a test area be prepared, particularly with any sensitive materials.

- Material Preparation:

- Any dirty or dusty aggregates should be washed thoroughly and dried prior to mixing to avoid discoloration and/or loss of strength.

- Aggregate may be damp but cannot be wet.

3

Mixing

Tools Needed: Heavy-duty paddle/drill mixer or suitable gravity mixer, large mixing tub, shovel, screeding tolls, and trowels.

Instructions:

- Add the appropriate amount of aggregate into the mixing tub or gravity mixer.

- Followed by the appropriate amount of both A & B components of the Xtreme Gravel Lock.

- (The 5kg units of Xtreme Gravel Lock will have 1/4 markings on each bottle, each 1/4 to be mixed with a maximum of 60 lbs. aggregate

- Mix for 5 minutes until homogeneous.

4

Application

- Apply the freshly mixed material onto the prepared substrate.

- Spread and level off with appropriate screeding tools or a trowel, then compact and smooth the surface with a trowel.

- Material may get sticky and more difficult to work with after 30 minutes or in higher temperatures.

5

Important Information

- Remain off the freshly applied areas and protect them from heavy rain for a period of min. 24 hours. Then the areas can be walked over carefully.

- In general, a strength test should be carried out before final clearance of the area after 7 days.

- The practice has shown that there are minerals for which the epoxy used can produce special effects such as darkening.

- Over time, this weathers off, and the mineral substance regains its natural color.

- In covered areas, the weathering process takes longer.

- With bright white minerals, a slightly yellowish color change may occur.

- These phenomena result from the contact between Xtreme Gravel Lock epoxy and mineral aggregate and are not a design defect.

- Color differences may occur until curing is complete, especially with strongly varying UV radiation.

- The gloss effect remaining after application will degrade over time from exposure to natural UV light.

- Despite careful processing, marginal detachment of individual grains cannot be ruled out.

GFTK Consumption Calculator

Use This GFTK calculator to find out how much product you need!

Please Note For The Calculator:

Calculations will only occur if all fields are filled in correctly.

Please ensure that a 0. is listed where the dimensions are under an inch.

For The Xtreme Elutriant:

Coverage is approximately 75 sq ft per bag of VDW 495.

Please View This PDF for Additional Information